Press Brake Operator Protection

Press Brake Operator Injury

Most press brake injuries occur when the operator gets their fingers or hand trapped between the dies during the fast downward motion of the ram. The tragic and most ironic thing is; the press brake operator, once trapped, in shock and experiencing extreme pain, reacts by making the machine continue through the stroke in what they believe is the only way to escape. Often this causes amputation by crushing, resulting in bone and tissue trauma that is medically not repairable. This is why using the best press brake operator protection becomes soo important.

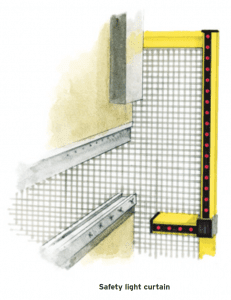

Light Curtain Example

Consider this. If the fast downward motion of the ram could be guarded by light curtains until the upper die is just 1/4 inch from the top of the material, the ram forced to stop. The light curtains muted (ignored) and the press brake operator required to consciously re-initiate the downward motion of the ram at slow speed. With the press brake operator protection in place the part could then be formed safely and without accidents like the one in the above example.

Ram Movement and Mute Points

Ram Movement

Ram movement during press brake operation can be generally described as fast downward travel until the tool is just about to begin forming the part. Then slower travel through the bend and then fast travel to the top stop position.

When the ram is traveling down (for up acting presses) at maximum speed, the ability of the machine’s ram stopping mechanism is drastically reduced as compared to the stopping time during the slow speed forming portion of the stroke.

Multi-Mute

Unfortunately, not many part shapes can be formed using the above example. The real world is not so flexible. But if there could be mute points higher than 1/4 inch, so that parts could be inserted into the die area after the ram reaches the mute point, then any configuration could be formed. Take it one step further; if the ram could be controlled to stop at programmed mute points on a given sequence of strokes, then the press brake operator could form complex shapes in the same manner as he/she would use a back gauge!

The only difference in the above operation with press brake operator protection in place is that the operator inserts the part into the die when the ram reaches the mute point instead of when the ram is at the top of the stroke. There is no lost production time and the benefit of the press brake operator protection helps keeps the operator safe from injuries.

Press Brake Operator Protection by Metal Tech Controls

We take press brake safety to the next level here at Metal Tech Controls. Our goal is to prevent injuries in the workplace. Our products are OSHA compliant. To get started today please contact us or give us a call at (800-516-5516).